How a Premier Injection Mold Manufacturer Can Improve Your Product Quality

Several factors can affect the quality of injection molded parts. Injection molding services should adhere to strict quality assurance standards to ensure that finished products meet or exceed customer expectations.

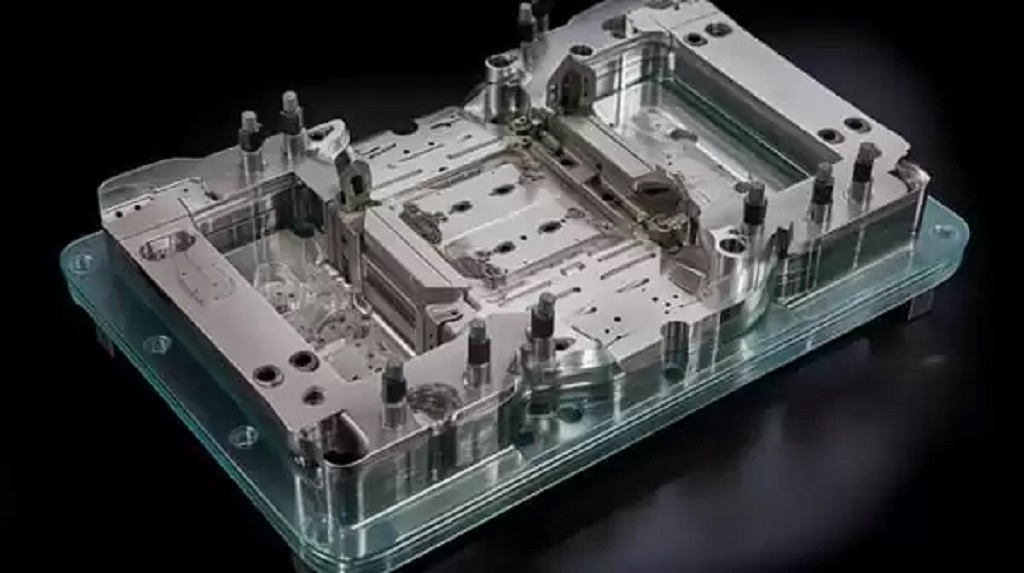

Quality assurance procedures include visual inspections, dimensional measurements, and material testing. Injection molds should also be optimized to minimize stress, warp, and shrinkage.

Design for Manufacturability (DFM)

DFM is an engineering process that optimizes production efficiency and cost, given a product’s form, fit, and function requirements. Unlike functional engineering, which focuses on performance or how well a design accomplishes its intended function, DFM aims to reduce manufacturing costs while maintaining product quality and viability.

Injection molding is one example where DFM can significantly decrease a final product’s cost. If the molded part isn’t designed for manufacturing, it may require costly repairs or be scrapped entirely. DFM can minimize these costs by reducing the number of components, simplifying component designs, and using standard parts whenever possible.

DFM can also help reduce product costs by minimizing production time and waste. For example, if a plastic material’s walls are too thick, they cool much slower and run the risk of sink areas. An engineer can resolve this issue with ribbing or other design changes that allow the plastic to cool quickly and correctly.

Material Selection

Material selection is an integral part of any engineering project. It affects a product’s functions, manufacturing process, and lifespan. Neglecting to select the suitable material can result in poor performance, higher costs, or even failure.

Many different materials are available, each with its own unique set of properties and characteristics. Sifting through this information and finding the facts to provide an apples-to-apples comparison can be challenging. A reputable manufacturer can help by serving as a trusted advisor.

A premier injection mold company will have stringent quality protocols to ensure dimensionally accurate plastic parts and consistent performance. This helps to ensure that a product meets industry standards and provides optimal function and longevity. It will also minimize maintenance costs and maximize sustainability. This is critical as environmental concerns are becoming increasingly important to consumers.

Surface Finishing

Surface Finishing improves the appearance, corrosion protection, wear resistance, and lubricity of a substrate. It is often used with other processes, such as injection mold manufacturing, to create a complete product.

A Surface Roughness Chart is a reference tool used to compare the roughness of different surfaces. It provides standardized samples that include a range of roughness levels with corresponding visual representations of textures like scratches, peaks, valleys, and waviness patterns.

A textured surface finish can increase a product’s grip, making it easier to handle and more durable for prolonged use. It also increases paint adhesion and sticker retention. A molded part that requires fastener attachment may incorporate plastic bosses for fastener attachment or threaded metal inserts that can be heat-staked in place. The injection mold designer needs to balance the strength of these features with the ability to properly align them in assembly and prevent misalignments that result in poor-quality products being sent to customers.

Quality Assurance

Injection molding is a cost-effective production process that offers superior quality. Its dimensional consistency and data-driven injection molding practices are ideal for complex or finely detailed plastic components and products.

To guarantee consistent quality, molds must be adequately maintained and free from residue or buildup that can negatively impact performance. Additionally, temperature thresholds need to be carefully monitored during the injection molding process to avoid warping or shrinkage of the final product.

Injection molding also allows for integrating fastener attachment methods, such as threaded metal inserts or heat-staked bosses that can be molded into the part. This provides for JIT assembly and kitting, which can save time and money and improve efficiency throughout the production process. It also helps to prevent bottlenecking, which can occur if certain parts are unavailable or there is an issue with machinery. Injection molding cells help to mitigate these issues and improve the overall quality of the finished product.