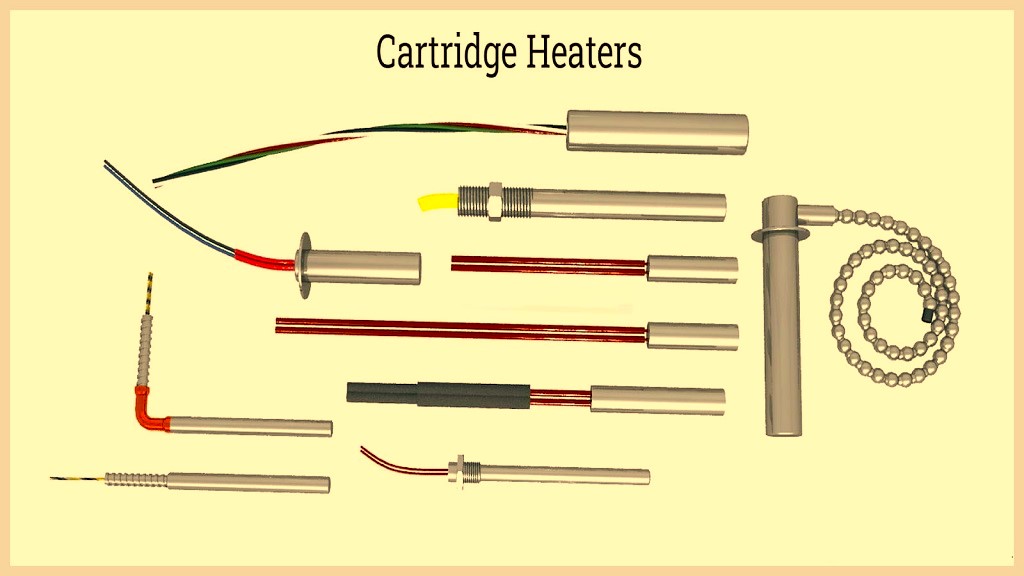

Maximizing Efficiency: Tips for Using Cartridge Heaters in Industrial Settings

In the dynamic world of industrial manufacturing, maintaining efficiency is not just beneficial—it’s essential. Cartridge heaters, when used appropriately, are powerful tools in this endeavor. These robust heating elements provide localized heat to a part of a machine where it is most needed, significantly enhancing the machinery’s performance and longevity. This blog post explores how to optimize the use of cartridge heaters in industrial settings, focusing on their placement, control systems, maintenance routines, insulation techniques, and integration with automation, to ensure energy-efficient operations. Let’s delve into the strategies that can elevate the performance and efficiency of your heating processes.

Optimal Placement and Configuration

Cartridge heaters are integral to numerous applications, from plastic processing to packaging machinery. To maximize their efficiency, the first step is strategic placement and configuration. Positioning cartridge heaters at equidistant intervals along a plat or barrel ensures even distribution of heat, minimizing hot spots and cold zones. This not only improves the quality of the product but also extends the lifespan of both the heaters and the equipment they serve. When considering cartridge heaters for sale, it’s crucial to select the right size and wattage for your specific application to optimize their effectiveness.

Temperature Control and Monitoring Systems

Transitioning to a more analytical tone, the importance of precision in temperature control cannot be overstated. Advanced temperature control and monitoring systems are vital for harnessing the full potential of cartridge heaters. These systems enable real-time adjustments and provide detailed feedback on the operating conditions, allowing for meticulous management of heat output. Implementing state-of-the-art sensors and controls reduces the risk of overheating and improves energy efficiency, which is paramount in high-stakes industrial environments.

Regular Maintenance and Cleaning Routines

Adopting a more instructional tone, let’s talk about maintenance. Regular maintenance and cleaning are paramount for ensuring that cartridge heaters operate at peak efficiency. Over time, dust, debris, and other contaminants can build up on the heaters, which can insulate the heat output and lead to inefficiency and potential equipment failure. Establishing a routine cleaning schedule to remove any buildup and check for wear and tear can greatly increase the operational lifespan of your cartridge heaters.

Proper Insulation Techniques

Shifting to a persuasive narrative, consider the impact of proper insulation—it’s a game changer. Effective insulation techniques around cartridge heaters can significantly reduce heat loss, leading to quicker heat-up times and lower electricity consumption. This not only helps in conserving energy but also boosts the overall efficiency of the industrial processes. Investing in high-quality insulation materials and ensuring they are correctly installed around the heaters can result in substantial long-term savings and performance improvements.

Integration with Automation Systems

Exploring the technological advancements, integrating cartridge heaters with automation systems can dramatically enhance process efficiency and product consistency. Automation allows for precise control over the heating elements, enabling them to adjust based on real-time data from the production line. This synchronization can reduce human error, streamline operations, and ensure that the heating is always at the optimal level for the task at hand, thus maximizing the output quality.

Energy-Efficient Operating Practices

Concluding with a visionary outlook, adopting energy-efficient operating practices is crucial for any forward-thinking business. Utilizing cartridge heaters with energy efficiency in mind involves not only selecting the right heater and installing it properly but also continuously evaluating the system’s performance. Implementing practices such as scheduling operations during off-peak energy hours and maintaining equipment regularly can substantially lower energy costs and reduce the carbon footprint of your industrial operations.

In conclusion, maximizing the efficiency of cartridge heaters in industrial settings involves a holistic approach—from the initial selection and placement to integration with advanced technologies and commitment to regular maintenance. By adopting these strategies, manufacturers can ensure optimal performance, significant energy savings, and a competitive edge in their respective markets.