The Benefits of Using Automated Crimping Solutions in Manufacturing

An automated crimping machine is your best bet for high-volume wire processing applications. Whether cutting to precise lengths, stripping with various options, or balancing terminal pressure, these machines do the job flawlessly daily.

Today’s CSC machines offer fast changeovers, process-specific technologies, and integration into plant management systems. Learn how these improvements can benefit your factory.

Increased Productivity

Automated crimping machines can significantly enhance the speed at which production is completed. This is important for cable production, where high rates are necessary to meet output specifications and deadlines.

In addition, automated crimping machines also offer precision and consistency in the crimping process, which is essential for ensuring quality output. Additionally, many crimping devices come equipped with integrated quality control processes such as crimp force monitoring, seal monitoring, and splice and knot detection.

In terms of training, automation can also improve productivity by allowing employees to work on different tasks without waiting for the applicator or terminal to be changed over. This can save up to 2 1/2 hours of shift time. Moreover, IoT-enabled crimpers such as the GC20 Cortex Crimper allow operators to access training materials on the machine’s touch screen easily.

Better Quality Control

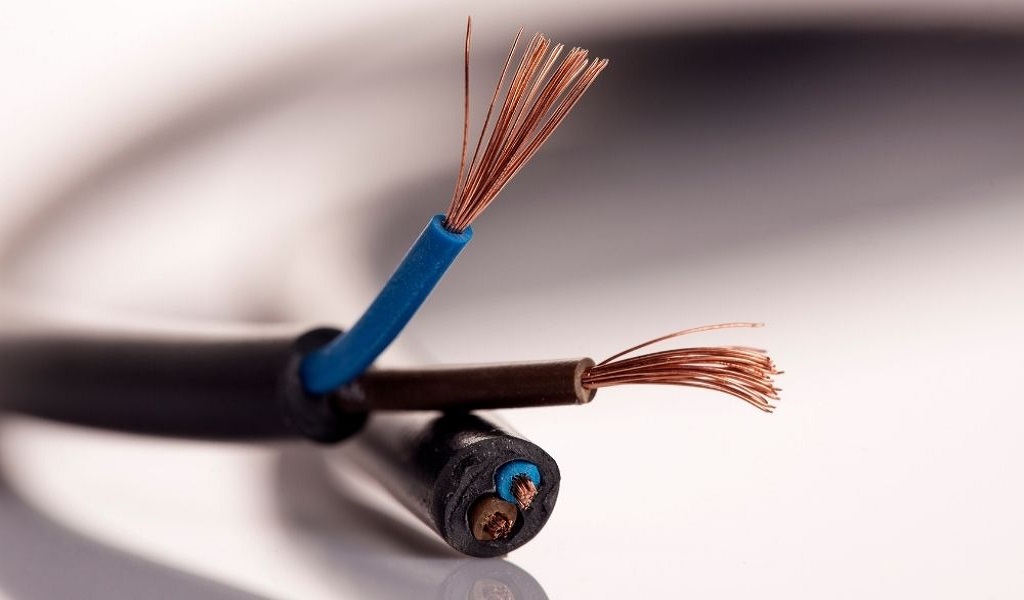

When it comes to crimping, quality is critical. High-quality crimps provide gas-tight connections that prevent oxygen and moisture from corroding the metals in the relationship. This is essential in the wiring harness industry, where electrical conductors must be securely connected to the rest of the circuitry.

Because crimping involves deforming and compressing two pieces of metal, problems often go unnoticed until later in the assembly process and can be expensive to fix. Automated crimping solutions Florence SC have monitoring systems that allow manufacturers to identify and resolve issues before they become a problem for their finished products.

The ability to cut, strip, and crimp all at once eliminates the need for manual process steps and can significantly reduce changeover times. Additionally, automated crimpers can work at much higher speeds than human technicians and aren’t susceptible to human error.

Increased Efficiency

Using an automatic crimping machine will significantly reduce the amount of manual labor required for production. This will allow your employees to focus on more important tasks while ensuring the job gets done correctly.

Smart crimpers use IoT to provide more data for the operator and make the process easier. They also feature easy-to-use touchscreens to improve crimping safety and efficiency.

A high-quality crimp produces gas-tight joints that prevent oxygen and moisture from corroding the different metals in the connection. This is especially important for electrical applications, where low electrical resistance is critical to safe and reliable performance. The crimping process also eliminates the need for soldering, which requires high temperatures and potentially hazardous materials. This makes it an ideal solution for remote and enclosed locations.

Lower Maintenance Costs

A crimp connection is low in electrical resistance, repeatable, gas-tight, and significantly faster than soldering. It is ideal for various materials and sizes applications where soldering cannot be used due to vibration or other usability factors.

Automated cut, strip, and crimp machines offer process monitoring that optimizes quality control while components are being made. This ensures that all crimps, seals, and connections are to the exact specification required for your application.

Additionally, a machine can monitor crimps for proper depth and wire gauge to avoid damage and wasted crimps. This reduces downtime and unscheduled maintenance costs for your plant. This means more uptime and more profit.

Increased Productivity

With the use of crimping solutions, manufacturers can save time and money. Instead of hiring extra staff to handle the manual task of assembling products and testing their quality, assembly workers can be put to work on more valuable lessons that will benefit their business.

Compared to soldering, crimping produces gas-tight connections that prevent oxygen and moisture from damaging the metals in the relationship. This means that production is more efficient than ever.

Fully automated crimping machines have integrated monitoring that optimizes quality control while the components are being made. These systems can detect splices and knots, crimp force, seal strength, and other variables to ensure that all operations are performed correctly. These features allow technicians to troubleshoot problems quickly and easily, and they reduce waste.