The Future of Warehouse Storage – Automation and Robotics

The warehousing industry is evolving quickly, thanks to innovations like automation and robotics, on-demand warehousing, warehouse management systems, vertical warehousing, and more. By adopting these trends, companies can save money and make their warehouses more efficient.

Warehouse automation technologies speed up product retrieval, order fulfillment, and inventory management processes. They also reduce errors and lower labor costs.

Increased Efficiency

Warehousing allows you to store extra inventory safely until you need it. It’s a great way to protect assets from theft and weather. Warehouses are often found at retail stores, distribution centers, cold storage facilities, and manufacturing plants.

Modern warehouses use cutting-edge technology to automate case handling and packing. While these technologies require an upfront investment, they decrease labor costs in the long term.

Warehouse business storage also helps you monitor manufacturing quality. This makes it easier to identify faulty products before they enter the supply chain and stop them from being sold. Continually evaluating and analyzing warehouse operations allows you to prioritize areas where improvements can be made. This can include minimizing backtracking, optimizing picking paths, and increasing the speed of operations. Ultimately, increased efficiency can lead to higher productivity and customer satisfaction.

Improved Productivity

Warehousing requires a warehouse management system, equipment to move inventory around, shelving, containers, and other facilities to protect and organize stock. Businesses may lease a warehouse, purchase one, or outsource their logistics to a third party managing storage.

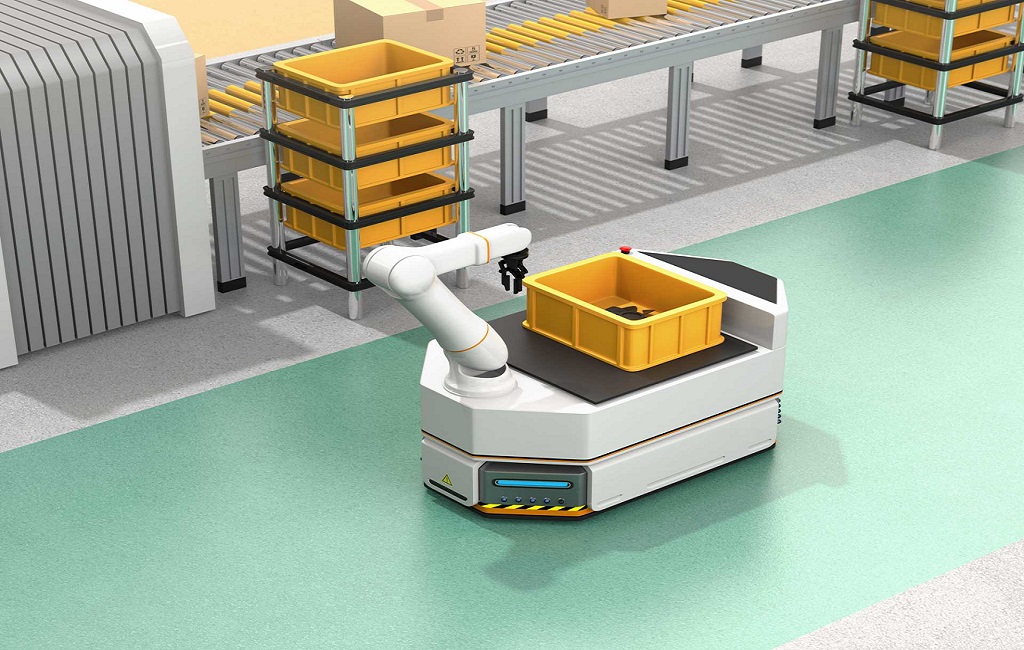

Automating and robotics can improve warehouse productivity by taking over time-consuming tasks from humans. For example, autonomous mobile robots can be programmed to pick, load, and unload heavy packages from shipment trucks and record the movement of that inventory with software, eliminating the need for manual tracking in high-velocity environments. Similarly, cartonization and picking automation systems streamline packing processes. Warehouse sorting robots utilize conveyors, arms, sensors, and algorithms to automatically send batch-picked items to the appropriate bin or storage area.

Enhanced Customer Service

Warehousing provides a secure place for brick-and-mortar retail and online stores to stock up on inventory. This allows for quick fulfillment once customers book a purchase, narrowing production gaps between demand and supply.

Automation and robotics are also making a big impact on warehouse storage. For example, robots can be programmed to do repetitive tasks like picking, sorting, and packing to free up employees for more challenging work. This boosts productivity and eliminates mistakes caused by human error.

Other innovations in warehouse storage include warehouse management tools, vertical warehousing, and on-demand warehousing. These new trends and ideas will help companies optimize their storage space, improve employee productivity, and achieve customer satisfaction goals. They will also provide an edge in the competition. Warehouse storage is a crucial part of the supply chain and is essential to business success.

Reduced Errors

Warehouse automation and robotics improve accuracy and eliminate errors caused by fatigue, overwork, and other human factors often occurring in manually operated equipment. This increases productivity and reduces damage to products, equipment, and warehouse structures.

Manufacturers seek ways to cut costs, increase quality, and expand operations without the risk of expensive mistakes. Warehouse storage automation and robotics are a perfect solution.

Autonomous mobile robots speed up order fulfillment, inventory checks, and more by moving items to their proper locations based on automated routes optimized for efficiency and flow. These robots can be programmed to perform specific tasks and assist human pickers. Warehouse storage automation also helps to sort and consolidate inventory based on dimensions, size, or type, making it easier to find specific product items.

Increased Safety

Warehousing involves holding your inventory longer, often in a more controlled environment. This includes high-level security measures, climate control, and other features to help you best manage your stock.

Warehouse storage requires a lot of workers, and it’s essential to ensure that they’re safe at all times. Automation systems can help reduce these risks. Palletizing robots can stack goods efficiently and avert damage while depalletizing robots can reverse the process without compromising safety standards.

Automated robots can also track and monitor inventory in real-time, providing more excellent safety than human operators. Knowing that your list is in good hands will give you peace of mind. This is especially helpful in disasters like earthquakes where human workers could be at risk.