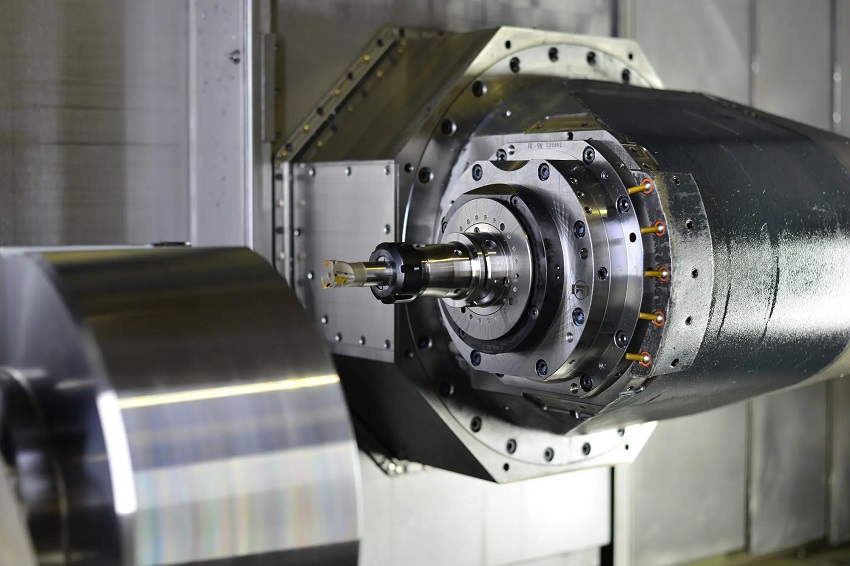

Functions of a CNC Router Spindle Motor

A spindle motor for a CNC router serves several purposes. Accuracy and location control for thread-cutting processes are a couple of them. The cooling method chosen depends on the budget and processing environment. Low-precision bearings can cause overheating and reduce the spindle motor’s service life. High-precision approaches will prevent overheating and ensure long-lasting service.

Position control for thread-cutting operations

A CNC router spindle motor can be controlled to adjust its speed and position during thread cutting. The machine usually features a sophisticated feedback system that continuously monitors the cutter’s speed and position. This machine can adjust its speed and work without operator intervention by using position control.

Typically, thread-cutting operations are done in the X and Y axes. The Y-axis is in the direction of the cutter and is parallel to the X-axis. In this mode, the spindle motor can interpolate from one plane to another without distorting the cutting process.

Another option for CNC router spindle motors is the servo motor. This type of motor offers smoother and more accurate movements compared to steppers. However, the servo motor is more expensive and requires tuning after installation. A single stepper motor can be found for under $40, whereas a single servo motor can cost over $400.

Another possible cause of thread-cutting operations failure is that the spindle motor or the control card is not working correctly. It may be due to a couple of reasons: the spindle is not moving in the correct direction, the spindle needs to move back to the origin position, or the limit switch needs to be fixed.

Accuracy of air-cooled spindles

Air-cooled CNC router spindle motors offer higher precision and less noise than their water-cooled counterparts. They run with a VFD, which allows them to have more precise RPM control. Another advantage of air-cooled spindles is their ability to run in either frequency or non-frequency conversion modes.

If the spindle has been idle for some time, it is essential to oil the spindle motor. It is also important to check the water quality, as it may need to be cleaner. Moreover, the temperature of the cooling chamber should be ambient, not below freezing.

Air-cooled CNC router spindles provide superior accuracy and torque than water-cooled counterparts. They are a good choice for beginners, and many CNC enthusiasts recommend them. They are typically more expensive than routers and require regular maintenance. However, they are often covered under a one-year warranty.

There are many advantages and disadvantages to using spindles. Choosing the right spindle depends on the type of workpieces you are milling. Some spindles can handle high-tensile materials, while others can take a more comprehensive speed range.

The most crucial feature of the air-cooled CNC router spindle is its accuracy. Its runout should be less than 0.005 mm, which is ten times more accurate than standard spindle motors. They should also have high-precision bearings. If the spindle has low-precision bearings, it may overheat and have a short service life.

Cost of brushless spindles

The spindle motor is one of a CNC router’s most crucial components. If you want to cut through heavy materials, you will need a high-powered spindle with more power. These motors come in air-cooled and water-cooled varieties. The former is quieter and can handle more power than the former. They are also better suited for heavier production work. However, consider several things before purchasing a spindle motor. First, decide if you will need a cylindrical or square spindle.

The Genmitsu GS-775 spindle motor can be up to 20,000 RPM and cut through material with incredible speed. It also has a low vibration and is quieter than many spindle motors. Initially designed to replace the ten thousand RPM motor on a Genmitsu 3018 CNC router, it can be used with any 775 motor frame. To connect the motor to the frame, you will need spade connectors.

Spindle speed is also essential, as a low-powered spindle can restrict your project. A high-speed spindle will ensure smooth cuts, but it can quickly overheat, causing it to stall and damage your machine. Water-cooled spindles are a good idea if a lot of dust is involved since the water will remove excess heat and prevent the motor from overheating.